November 2025

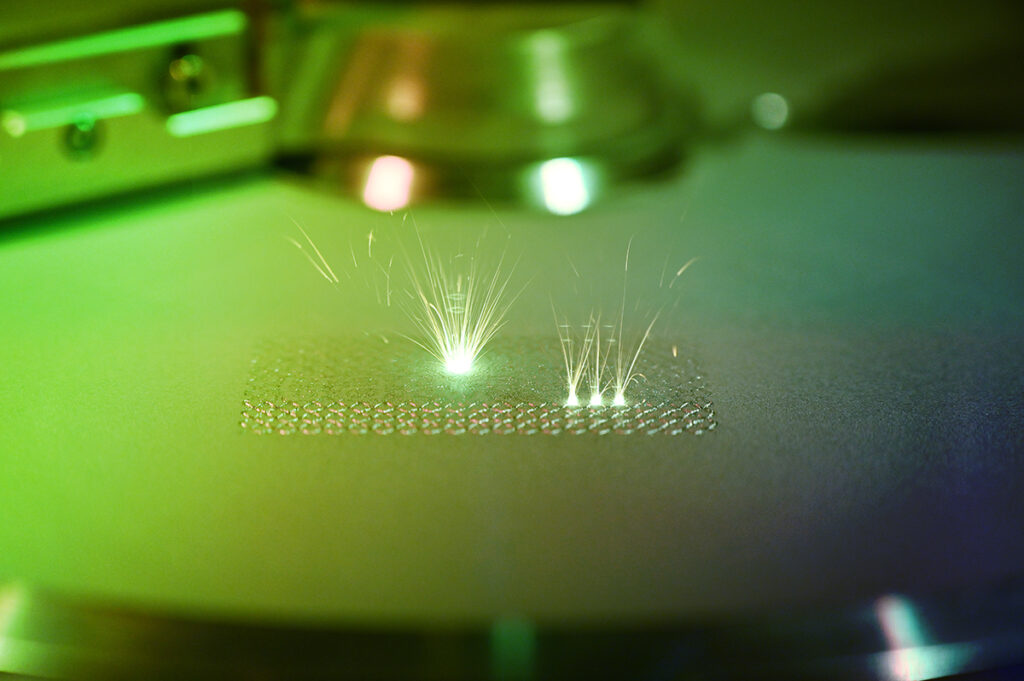

ASTM has joined the Digitally Enabled Competitive & Sustainable Additive Manufacturing (DECSAM) project. Led by Airbus, this £38 million, four-year UK aerospace programme will develop and deploy the latest additive manufacturing (AM) technologies—such as beam shaping and in-situ process monitoring—to make metal laser powder bed fusion (L-PBF) AM more cost-effective, productive, and sustainable for flight-ready parts. The project, which runs until June 2028, is a research and innovation initiative funded through Innovate UK, the Aerospace Technology Institute (ATI), and the UK Department for Business and Trade.

By prioritising resource efficiency, material reuse, and circular design principles, DECSAM aims to reduce waste and carbon intensity across the AM value chain, supporting the aerospace sector’s transition toward net-zero manufacturing and more sustainable aviation.

The project brings together 11 leading organisations covering aerospace OEMs, Tier 1&2 suppliers, SMEs and research institutes, providing full UK AM manufacturing chain coverage. The partners including Airbus Operations Limited (lead), Renishaw plc, ASTM International UK, Authentise Ltd, The Manufacturing Technology Centre Limited, GKN Aerospace Services Limited, Additive Manufacturing Solutions Ltd, APEX Additive Technologies Ltd, Domin Limited, University of Sheffield, and ToffeeX Limited.

“Additive manufacturing can unlock new efficiencies in aerospace, lowering costs, optimising material use, reducing weight, and consolidating complex assemblies into single parts,” said Jacqueline Castle, Chief Technology Officer at the Aerospace Technology Institute. “DECSAM unites a strong consortium to accelerate adoption in civil aerospace, aligning closely with the ATI’s additive manufacturing strategy to drive future economic growth and sustainability.”

DECSAM will demonstrate an integrated, digitally connected AM supply chain, from alloy selection and build strategies to post-processing, inspection and factory scale-up. “In order to demonstrate AMs future cost competitiveness for aerospace applications”.

What DECSAM will deliver

To cut part cost, raise quality, and shorten design-build-test loops for aerospace applications, DECSAM is structured around four innovation pillars:

- Performance: new and improved alloys, multi-physics modelling and physics-driven design)

- Productivity: high-power lasers, beam shaping, advanced scan strategies, in-situ monitoring and closed-loop control

- Scalability: end-to-end digital thread, automated sustainable factory concepts, and efficient post-processing/inspection

- Application: Integration of technologies developed to demonstrate overall cost benefit on target product applications.

Planned outputs include ground and flight-test demonstrators, validated recycled/repurposed powder routes, widened powder specifications, verified parameter themes for quality and throughput, in-process monitoring software offerings, and guidance for routes to qualification and certification, all targeted at accelerating industrial exploitation.

ASTM will play a leading role in amplifying DECSAM’s outcomes—ensuring its findings, standards insights, and adoption pathways reach the global manufacturing community. Leveraging its UK-based AM operations and world-class Centre of Excellence, ASTM will provide deep expertise in qualification, certification, data interoperability, and sustainable materials practices. This engagement builds on the recent launch of ASTM International UK, a dynamic new regional hub created to accelerate additive and advanced manufacturing qualification, standardization, and industrial adoption across the UK and Europe

“The UK government’s investment in green aerospace innovation is a strong signal that sustainable manufacturing is both a national priority and a global opportunity,” said Andrew G. Kireta Jr., president of ASTM International. “DECSAM exemplifies the kind of industry-led collaboration needed to unlock additive manufacturing’s potential at scale—and ASTM is proud to contribute to its success.”

Why it matters

L-PBF is flight-proven, but wider uptake is constrained by end-to-end productivity gaps, fragmented data/QA, and reliance on overseas steps (powder, HIP, advanced heat-treat). DECSAM closes those gaps by linking UK materials supply, machine capability, in-process quality assurance, a robust digital thread, and factory scale-up—so parts are repeatable, cost-competitive, and producible at volume in the UK, supporting net-zero 2050.

The programme is business-case led: recycled/UK-made powders; optimised build and nesting; in-process monitoring with closed-loop control to reduce or eliminate HIP/CT where feasible; and parameter/alloy development to cut finishing time. Cost-modelled demonstrators (e.g., an aircraft floor beam) show the shift from today’s “as-is” to a digitally connected, production-ready “to-be” at a cost point which enables AM to buy its way into serial aerospace production.

Focus use cases include ultra-efficient wing & engine structures and hydrogen subsystems (conformal heat exchangers, fuel-cell manifolds). Alongside performance gains, DECSAM mitigates single-source casting risks, on-shores critical pre-form manufacture, and advances compact AM-enabled actuation toward power-by-wire—delivering more right-first-time, certifiable parts, shorter lead times, a resilient UK supply chain, and cleaner aerospace manufacturing.

DECSAM at a glance:

- Value & timing: £38 million ; June 2024 – June 2028 (48 months).

- Leadership: Airbus (project lead) with 11 project partners across OEMs, Tier-1s, SMEs, RTOs and academia.

- Innovation pillars: Performance, Productivity, Scalability, Demonstration for L-PBF.

- Planned outputs: Ground and flight demonstrators; recycled/reused powder routes; in-process monitoring with closed-loop control; a connected digital thread; factory design for scale-up; and clear pathways to qualification and certification.

Funding acknowledgement: This work is supported by the ATI Programme: a partnership of the Aerospace Technology Institute, the Department for Business & Trade and Innovate UK.

Notes to editors: Consortium: Airbus Operations Limited (lead), Renishaw plc, ASTM International UK, Authentise Ltd, The Manufacturing Technology Centre Limited, GKN Aerospace Services Limited, Additive Manufacturing Solutions Ltd, APEX Additive Technologies Ltd, Domin Limited, University of Sheffield, and ToffeeX Limited.

Media contacts: enquiries to uk@astm.org