Consortium for Materials Data and Standardization

Consortia for Materials Data and Standardization (CMDS) enables companies of all sizes from across the entire additive manufacturing ecosystem to collaborate on standardizing the requirements and best practices for materials data generation and creating, curating, and managing the data needed to accelerate the industrialization and full adoption of AM technologies.

The AM CoE CMDS, in coordination with members and with input from regulatory agencies, will accelerate adoption of AM technologies through standardization by:

Establish requirements and develop best practices for creating robust AM material datasets

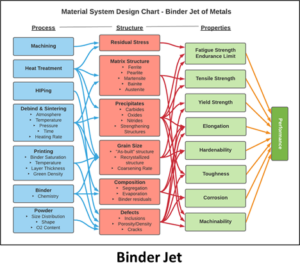

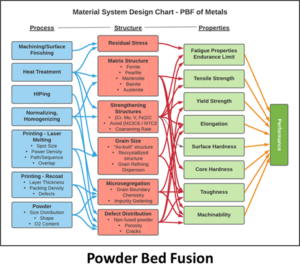

- Focus on understanding key Process-Structure-Property relationships

- Identify key sources of variability and quantify sensitivities

- Ensure linkage between specimen generated data to part production

- Establish guidelines for assessing quality and pedigree of existing materials datasets

Consortia-funded R&D projects create shared high-pedigree “reference” material datasets

- Generation of Machine-agnostic datasets to support process-based standards

- Establish methods for determining data equivalency based on material structure

- Trusted datasets support advancing physics-based, probabilistic and AI/ML modeling tools for process optimization and rapid qualification

- Mature real-time Quality Assurance using in-situ data to improve defect detection/prediction

Maintain secure member-only Data Management System

- Optimize entire material data generation workflow for automation and interoperability

- Incorporate Common Data Dictionary, Data Exchange Formats and Pedigree standards

- Implement FAIR principles (Findability, Accessibility, Interoperability, and Reuse)

- Minimize data processing costs (capture, ingestion, curation, analysis, learning)

Transferring lessons learned and consortium approved materials data to F42 standards development committees

- Improve drive consistency of materials data generation through industry to ensure comparability and combinability of data

- New and improved AM material specifications with property and structure requirements based on robust datasets

5 Reasons to join AM CoE CMDS

- Leverage R&D and material dataset creation expertise from the AM CoE and a large member base representing the entire AM value stream.

- Unique, first of its kind direct relationship between standard development, industry, academia, government, and research organizations.

- Close collaboration with MMPDS (MoU with ASTM), CMH-17, NIST and other international influencing agencies which provide guidance on material data generation requirements and data reduction methods to the consortium.

- Opportunity for direct access and to influence ASTM and other external funded research programs focused on developing materials data and knowledge that will influence future industry standards and requirements from various regulatory agencies.

- Ability to positively impact your supply chain through data-driven AM standards while preserving a unique role for your organization.

Value Proposition

- Shared funding model delivers a minimum of 10:1 ROI for materials data.

- Multiple materials and AM modality work streams enable greater opportunities for member AM applications.

- Using consortium approved guidelines drives consistent data generation practices throughout industry and ensures broad acceptance and increased trustworthiness of member data.

- Consortium driven highly efficient data management and processing tools and automated data workflows results in lower overall dataset generation costs.

- Material data equivalency standards enable rapid qualification and buy-in of new technology (machines, feedstock, etc.) with minimal new testing required and increases the comparability and potential combinability of datasets.

- Leverage combined resources toward a common vision for Model Assisted Rapid Qualification (MARQ) using “shared” high-quality datasets to support development and validation of modeling, simulation and real-time Quality Assurance tools.

“We are excited to join CMDS, where we will work with the consortium to generate the data needed to create materials and test standards necessary to accelerate qualification of our high performance aluminum alloys for additive manufacturing.”

Ravi Shahani, Chief Engineer, Constellium

“Our mission for metal binder jetting at Markforged is to establish it as a production manufacturing process widely adopted across major industries. Joining CMDS will help contribute to this mission by developing standards on sinter-based AM so engineers can trust the underlying process and leverage its full potential.”

Ross Adams, Business Development Manager, Markforged

“NSL Analytical is excited to participate in the ASTM CoE Consortium for Materials Data and Standardization. Unlocking common approaches to qualifying new materials is essential to developing and maturing the standards that are the foundation for expanded additive production for industrial applications. We look forward to contributing our testing thought leadership and capabilities to drive additive advancements.”

Ed Herderick, Vice President, Science and Technology Development, NSL Analytical

“GE Additive is pleased to continue its engagement with the ASTM Industry Consortium. As a company that offers the entire additive ecosystem, from feedstock to finished parts, we recognize the importance of developing highly pedigreed material property data sets. By coming together to define a common approach to materials characterization, we hope to drive further understanding and expansion of the additive industry as a whole.”

Amber Andreaco, Section Manager – Materials & Powders, GE Additive

“The Boeing team is excited to join the AM CoE Industry Consortium and collaborate with the AM CoE industry partners to mature and accelerate the industrial adoption of additive manufacturing. The collective AM expertise of the partners provides the broad perspective needed to advance the AM industry and drive towards the common AM standards needed for sustained adoption.”

Nicholas Mule, Director, Boeing Additive Manufacturing Intelligence Center

“This initiative connects industry, academia, and government teams to accelerate the path for additive adoption, moving additive manufacturing from a process with significant financial barriers to a standard manufacturing process for widespread use. Raytheon Technologies is bringing their experience and diverse research and data to help create the standards and qualification methods necessary.”

Jeff Shubrooks, Raytheon Missiles and Defense Additive Manufacturing Technology Area Lead

“ORNL joined this consortium to support critical standards development efforts and contribute to the creation of common data formats for additive manufacturing. Our researchers are enthusiastic about the collaboration opportunities with industry partners who can provide regular feedback on ORNL’s roadmaps and planned research efforts in this technical area.”

Research Team, Oak Ridge National Laboratory

“The entire Sigma Labs team is delighted to be collaborating with part producers and end users through this ASTM Consortium to map key items from feedstock production through final QC/material data sets. Our mission is to support the growth of the industry by providing visibility into in-process quality that can provide data to link the process workflow and help form standards that can accelerate material and process development.”

Jacob Brunsberg, CEO, Sigma Labs, Inc.

“AddUp is pleased to be a founding partner in the AM CoE Industry Consortium alongside other industry leaders with an aim to mature and accelerate the industrial adoption of additive manufacturing. The consortium’s focus will be instrumental in overcoming known impediments to the adoption of metals-based additive manufacturing, developing a broader technical basis for high-priority standards, and making those results available across industry through the established leadership of standards development within ASTM.”

Rush LaSelle, CEO of AddUp Inc.

“As a world leading manufacturing solution integrator, Morf3D made a strategic decision to join the AM CoE Consortium for Materials Data and Standardization to collaborate with world leading entities to facilitate and accelerate generation of materials datasets and standardize best practices. We are delighted to join a diverse team representing the entire ecosystem in metal additive manufacturing, from academia, application owners, to machine manufacturers, materials producers, post-processing service providers, monitoring solution providers and Morf3D as an AM solution integrator to develop standards with the guidance of ASTM.”

Dr. Behrang Poorganji, Vice President of Materials Technology, Morf3D

“Collaboration with the AM CoE consortium and industry partners is critical to advancing the potential of additive manufacturing, as well as the innovation work in smart manufacturing. We are proud to be a part of this timely AM CoE initiative. Our focus on industrializing additive part production strategically aligns with AM data standardization, both of which can move industry adoption to a whole new level. Working with our partners, we can evolve our holistic approach to building better, more precise AM parts from design engineering to production to inspection.”

Paul Rogers, President and CEO, Americas, Hexagon’s Manufacturing Intelligence Division

Questions? Contact:

Richard Huff

ASTM International Additive Manufacturing Business Development Manager

ASTM International CMDS Manager

Email: rhuff@astm.org

Tel: +1 (202)948-4919