About

The ASTM International Conference on Advanced Manufacturing (ICAM) is the premier annual forum where the global advanced manufacturing community converges to shape the future of industrial production. ICAM 2026, hosted by the ASTM Global Advanced Manufacturing Programs Division and supported by more than a dozen ASTM technical committees, brings together the leaders, innovators, and practitioners who drive technology from early exploration to industrial deployment.

ICAM focuses on the full lifecycle of manufacturing innovation—pre-industrialization research, standards that support scale-up, and post-industrialization practices that strengthen reliability and performance—across sectors such as aerospace, defense, energy, medical, automotive, and microelectronics. The conference provides a collaborative environment where end users, researchers, government agencies, and solution providers work together to build the consensus, pathways, and implementation strategies needed for advanced manufacturing.

Key focus areas include:

- Industry standards and shared frameworks

- Design methods for scalable manufacturing

- Qualification pathways and responsible adoption

- Process and system innovations

- Advanced materials and integrated manufacturing processes

- Data, modeling, and digital manufacturing ecosystems

| ICAM 2026 - General Submission Timeline | |

|---|---|

| Abstract Submission Opens | Dec 15 (Mon) |

| Abstract Submission Deadline | March 6 (Fri) |

| Notification to Accepted Speakers | May 8 (Mon) |

| Registration Opens | May 1 (Fri) |

ICAM is the place where technical decision makers from around the world exchange insights, present leading-edge work, and build the technical and strategic relationships that move advanced manufacturing forward. The conference supports the transition of ideas, methods, and technologies into production-ready solutions, ensuring that innovation isn’t something stuck in a lab, but delivered to the front lines.

Abstracts

This is a unique opportunity to showcase your research and technical expertise to a global audience of industry professionals, academics, and thought leaders.

Authors are encouraged to submit an abstract of no more than 500 words, outlining the scope of their presentation and aligning with one of the conference topics listed below. Accepted abstracts will secure a presentation slot at ICAM 2026.

Symposia Topics include:

- Industrial Applications – aviation, space, medical, energy, etc.

- Value Chain – directed energy deposition, fatigue and fracture, in-situ monitoring, etc.

- Industry 4.0 – AI/ML, modeling & simulations, security, etc.

- Non-Metallic Materials – polymers, composites, ceramics, microelectronics, etc.

Selection Criteria

Presentation slots will be allocated based on the merit and relevance of the submissions to the conference agenda. Timings and formats for speaking slots will be finalized as the program is developed, based on the subject matter.

Submissions will be evaluated based on the following:

- Relevance and importance of the topic to conference attendees

- Inclusion of an end-user as a lead or co-presenter

- Objective and educational content

- Clearly defined benefits for attendees

- Knowledge and experience of the speaker(s)

Please note:

When submitting your abstract through the submission portal, you will need to select the symposium to which you wish to submit your work. Please be aware that your submission may be reassigned to a different symposium based on its relevance and the number of abstracts already accepted.

Please select “Invited Presenter” only if you have received an invitation from the ICAM 2026 Scientific Organizing Committee.

Additionally, presenters are limited to a maximum of two submissions, and each presenter is allowed only one “invited” presentation.

Students

Download the Student Research Showcase Flyer

ICAM 2026 Student Research Showcase

Full-time/part-time graduate and undergraduate students will participate in the Student Presentation and Poster Competition that will be held in conjunction with ICAM 2026. Each of the top presentations in the three competition categories will receive $750, and the best overall presentation among them will receive an additional $250.

Prizes and Awards:

Oral Presentation The Top 20 finalists will be grouped and evaluated within one of three categories listed below. A prize of $750 will be awarded to the top presentation in each of the three categories. In addition, the best overall presentation among the category winners will receive an additional $250.

- AM Process: parameter effects, process monitoring, control strategies, and emerging AM process technologies

- AM Material: material development, characterization, properties, and performance in AM applications

- AM Mechanical Behavior: strength, fatigue, fracture, modeling, simulation, or validation of mechanical behavior in AM parts

Poster Competition

- First Place: $1000

- Second Place: $750

- Third Place $500

*All awardees will also receive a plaque.

*IMPORTANT*

— Students can only submit two abstracts in total.

— Each abstract must be submitted to a different student category (e.g., each student cannot have 2 abstracts submitted to the Poster Competition).

| Abstract Submission Deadline | March 6 (Fri) |

| Notification to Accepted Students | May 8 (Fri) |

| Presentations due for Oral Presentation Competition (Round 01) | June 15 (Mon) |

| Oral Presentation Competition (Round 01) Results | August 3 (Mon) |

| In-Person Final Evaluations (Round 02) --- Student Oral Presentation Competition | September 28 (Mon) |

| Student Poster Competition | September 28 (Mon) |

| Student Oral Presentation Sessions | September 29 (Tue) – October 1 (Thu) |

Sponsorship

Download the Sponsorship Brochure

Why Sponsor ICAM 2026?

ICAM is the gathering point where advanced manufacturing moves from possibility to production. ICAM 2026 brings together the organizations shaping the next decade of industrial capability, uniting research, engineering, and supply-chain leaders around the frameworks and pathways that accelerate real-world adoption.

As a sponsor, your organization is positioned as a strategic partner in this global dialogue, contributing to the technical, digital, and operational foundations that carry technologies from the lab into industrial environments.

Benefits of Sponsoring ICAM

-

Strengthen industry presence with high-value visibility across a global audience of decision-makers

-

Demonstrate leadership in emerging technologies through curated thought-leadership opportunities

-

Build meaningful connections with innovators, end users, and government stakeholders

-

Align with the conversations shaping future manufacturing ecosystems

-

Help advance the frameworks and consensus needed for scalable, production-ready solutions

For inquiries or to secure your sponsorship, contact icam@astm.org.

Symposia

Organizers

Highlights

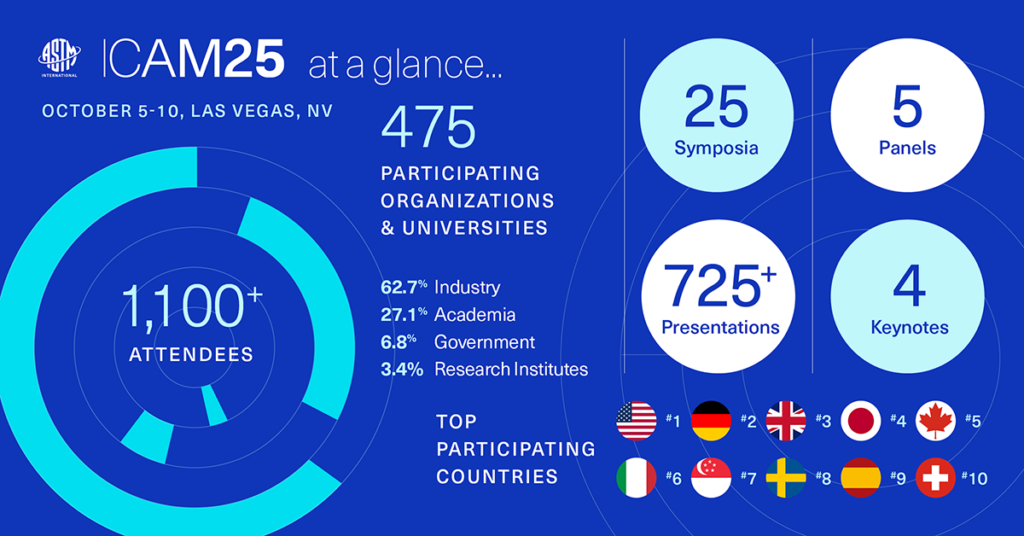

The ASTM International Conference on Advanced Manufacturing (ICAM 2025) was held October 6–10, 2025, at the Westgate Las Vegas Resort & Casino in Las Vegas, Nevada, USA. Hosted by the ASTM International Additive Manufacturing Center of Excellence (AM CoE) and supported by over a dozen ASTM technical committees, ICAM 2025 marked the tenth year of ASTM’s flagship event for additive and advanced manufacturing.

For a taste of last year’s event, watch the videos below:

More highlights can be found on the ICAM 2025 event page.