ASTM International UK joins £38M DECSAM programme to scale sustainable aerospace additive manufacturing

November 2025

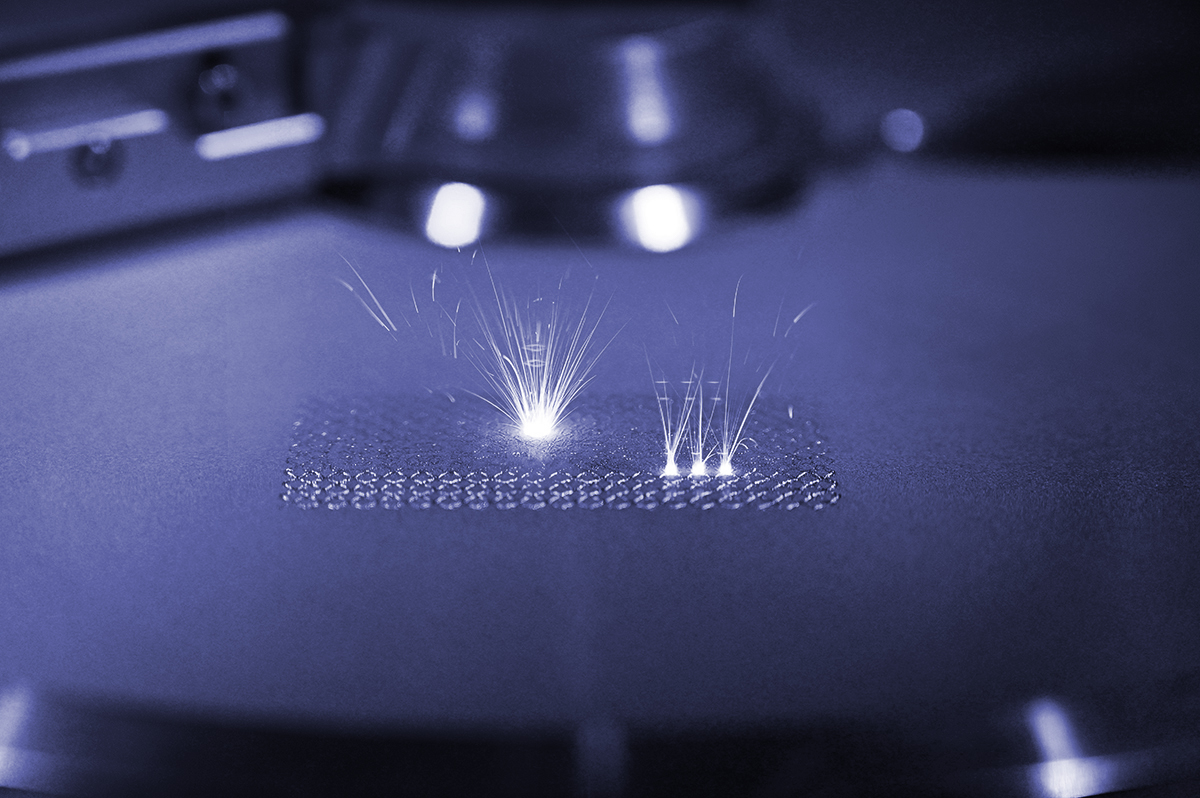

The UK’s aerospace and advanced manufacturing community has joined forces in the £38 million Digitally Enabled Competitive & Sustainable Additive Manufacturing (DECSAM) programme—a major collaborative effort to scale metal additive manufacturing for next-generation aircraft. Led by Airbus, this £38 million, four-year UK aerospace programme will develop and deploy the latest additive manufacturing (AM) technologies—such as beam shaping and in-situ process monitoring—to make metal laser powder bed fusion (L-PBF) AM more cost-effective, productive, and sustainable for flight-ready parts. The project, which runs until June 2028, is a research and innovation initiative funded through Innovate UK, the Aerospace Technology Institute (ATI), and the UK Department for Business and Trade.

By prioritising resource efficiency, material reuse, and circular design principles, DECSAM aims to reduce waste and carbon intensity across the AM value chain, supporting the aerospace sector’s transition toward net-zero manufacturing and more sustainable aviation.

The project brings together 11 leading organisations covering aerospace OEMs, Tier 1&2 suppliers, SMEs and research institutes, providing full UK AM manufacturing chain coverage. The partners including Airbus Operations Limited (lead), Renishaw plc, ASTM International UK, Authentise Ltd, The Manufacturing Technology Centre Limited, GKN Aerospace Services Limited, Additive Manufacturing Solutions Ltd, APEX Additive Technologies Ltd, Domin Limited, University of Sheffield, and ToffeeX Limited.

“Additive manufacturing can unlock new efficiencies in aerospace, lowering costs, optimising material use, reducing weight, and consolidating complex assemblies into single parts,” said Jacqueline Castle, Chief Technology Officer at the Aerospace Technology Institute. “DECSAM unites a strong consortium to accelerate adoption in civil aerospace, aligning closely with the ATI’s additive manufacturing strategy to drive future economic growth and sustainability.”

DECSAM will demonstrate an integrated, digitally connected AM supply chain, from alloy selection and build strategies to post-processing, inspection and factory scale-up. “In order to demonstrate AMs future cost competitiveness for aerospace applications”.

What DECSAM will deliver

To cut part cost, raise quality, and shorten design-build-test loops for aerospace applications, DECSAM is structured around four innovation pillars:

- Performance: new and improved alloys, multi-physics modelling and physics-driven design)

- Productivity: high-power lasers, beam shaping, advanced scan strategies, in-situ monitoring and closed-loop control

- Scalability: end-to-end digital thread, automated sustainable factory concepts, and efficient post-processing/inspection

- Application: Integration of technologies developed to demonstrate overall cost benefit on target product applications.

Planned outputs include ground and flight-test demonstrators, validated recycled/repurposed powder routes, widened powder specifications, verified parameter themes for quality and throughput, in-process monitoring software offerings, and guidance for routes to qualification and certification, all targeted at accelerating industrial exploitation.

Partner Descriptions

Airbus

As DECSAM project lead, Airbus is responsible for strategic integration and monitoring of activities, stakeholder management, exploitation planning, and progress reporting to Innovate UK. Airbus is leading activities for the improvement of Additive Manufacturing part performance through the development of materials and processes, and through the development of optimisation-driven design techniques. Additional project responsibilities include technical contribution to certification, qualification, modeling, simulation, industrialisation, scalability, and digital thread. Airbus will integrate the technologies developed within DECSAM into the production of key components to demonstrate performance improvements and process cost-competitiveness.

ASTM

ASTM will play a leading role in amplifying DECSAM’s outcomes—ensuring its findings, standards insights, and adoption pathways reach the global manufacturing community. Leveraging its UK-based AM operations and world-class Centre of Excellence, ASTM will provide deep expertise in qualification, certification, data interoperability, and sustainable materials practices. This engagement builds on the recent launch of ASTM International UK, a dynamic new regional hub created to accelerate additive and advanced manufacturing qualification, standardization, and industrial adoption across the UK and Europe

Authentise

Authentise will establish an end-to-end digital thread across the additive-manufacturing supply chain by deploying its FLOWS MES, defining technical data packages, and enabling dynamic production scheduling across supply-chain and supply-network scenarios. Together, these capabilities aim to strengthen resilience and reliability while reducing costs in AM operations.

The University of Sheffield

The University of Sheffield is an established academic partner, bringing a strong record of industry-focused research and deep fundamental insight. Within DECSAM, it will leverage the Henry Royce Institute for Advanced Metals Processing and its open-architecture AM platform to explore and implement advanced machine-control and validation methods, underpinned by internationally leading capability in AM modelling and simulation. The work will be delivered by a team of four academics (Prof. Iain Todd (P.I.), Prof. Hector Basoalto, Prof. Kathy Christofidou, Dr Pablo Baldivieso) and seven senior researchers. Sheffield will be a partner in DECSAM until December 2027.

ToffeeX

ToffeeX will support DECSAM by developing new physics-driven generative design software such as topology optimisation, integrated physics simulation, and ML-based surrogate modelling tools. These will be used to generate designs for high-performance components. Features such as design and manufacturability constraints ensure both interpretability and manufacturability of results, while advanced algorithms enable rapid design generation, accelerating the design–manufacture–test cycle.

Apex Additive Technologies

Apex Additive Technologies will extend powder life and reduce costs by implementing advanced process control and conditioning for reuse; benchmark, validate, and deploy macro-simulation workflows to enable true right-first-time operations; and validate and implement beam-shaping to balance quality with productivity. It will also develop and qualify a broad range of materials to expand capability and support partner applications with Airbus, Domin, Renishaw, and GKN, while piloting the ASTM AM Certification Program.

Additive Manufacturing Solutions

Additive Manufacturing Solutions (AMS) is a knowledge and capability hub delivering metal AM from prototype through to production, backed by qualification and testing, sustainable and next-generation material development, and training via its in-house academy. Within DECSAM, AMS will focus on boosting productivity through novel scan strategies and developing sustainable material feedstocks.

The MTC

The MTC will focus on accelerating AM productivity by optimising shaped beam parameters within the laser powder bed fusion process, supported by novel simulation and in-process monitoring methods. It will lead the Scalability work package to support scale-up of production through digital thread integration, automated factory design, sustainability data capture, and scalable post-processing and inspection techniques to overcome manufacturing bottlenecks. The MTC will also support dissemination and demonstration into the AM supply chain for aerospace.

Renishaw

Renishaw plc will support DECSAM by developing processes and parameters for high-temperature materials, improving process control through modelling and simulation, and extending powder life for greater feedstock sustainability. Using its RenAM 500 series metal additive manufacturing systems, Renishaw will also deliver improvements to productivity, quality, and automation to reduce non-productive time and lower overall labour costs.

GKN Aerospace

GKN Aerospace is a risk and revenue sharing partner in a number of leading aero-engines and will leverage this position to integrate multiple DECSAM-developed technologies to demonstrate the cost effectiveness of powder bed additive manufacturing for future engine products. GKN will lead the assessment and development of new material systems including sustainable feedstock, part-based simulation methods, and co-ordinate both in-situ inspection and monitoring, and Laser Powder Bed productivity studies.

Domin

Domin is a scale-up based in Bristol, United Kingdom, developing and manufacturing their patented, high-performance technology for hydraulic systems, including high-speed control valves and ultra-compact pumps. Domin combines modern tools like metal 3D printing, modern electronics, and advanced design and simulation techniques, to deliver unparalleled performance and reliability. Domin’s mission is to transform motion control in globally important industries like industrial manufacturing, automotive, and aerospace.

Quotes

ASTM

“The UK government’s investment in green aerospace innovation is a strong signal that sustainable manufacturing is both a national priority and a global opportunity,” said Andrew G. Kireta Jr., president of ASTM International. “DECSAM exemplifies the kind of industry-led collaboration needed to unlock additive manufacturing’s potential at scale—and ASTM is proud to contribute to its success.”

The MTC

“As the National Centre for Additive Manufacturing, we’re excited to help improve the cost-competitiveness of the technology so that it can be scaled and adopted more widely across the UK’s aerospace industry. This large programme is an opportunity to make a major step forward towards this and we’re proud to be playing a central role in its delivery and working with excellent partners,” said Dr. David Brackett, Chief Engineer – Digital Engineering, MTC.

GKN Aerospace

Sébastien Aknouche SVP Material Solutions at GKN Aerospace said: “The DECSAM Project strengthens GKN Aerospace’s broader additive manufacturing capabilities, delivering environmental, performance, and supply chain advantages over traditional material supply chains. With growing demand for additive solutions from all engine customers, this project enhances our UK technology base and positions us for future production growth.”

The University of Sheffield

“As the sole academic partner, this project highlights the University of Sheffield’s leading expertise in additive manufacturing and computational modelling. This cross-cutting research project will allow us to accelerate our work in advanced manufacturing and computation modelling, bringing together diverse areas of expertise that wouldn’t otherwise be possible at this speed. The additive manufacturing research we’ll be conducting at the Henry Royce Institute will not only contribute to their key performance indicators but also directly support two of our university’s spin-out companies: Instruct3D and m2i2. We’re especially excited about the potential for this research to integrate directly with the AMRC’s Factory+ connected manufacturing framework,” said Prof. Iain Todd, Professor of Metallurgy and Materials Processing, University of Sheffield.

Authentise

“Additive manufacturing can only deliver on its aerospace promise if the entire supply chain is digitally connected and traceable. That’s where Authentise comes in. By establishing the digital thread across DECSAM partners we’ll help turn today’s research into certifiable, production-ready solutions faster, cheaper, and more sustainably.”

“Too often, additive manufacturing gets stuck in pilots because the data and workflows aren’t connected. DECSAM gives us the chance to prove that a real digital thread across materials, machines, and partners doesn’t just make aerospace parts cheaper and faster — it makes the whole supply chain more resilient and sustainable. That’s the only way this industry scales.”

Andre Wegner, CEO, Authentise Ltd.

Domin

“This grant is a powerful validation of the work Domin is doing to lead the next generation of aerospace manufacturing. Metal 3D printing is a transformative technology, and we are already redefining industry standards through it, but to make it truly viable for aerospace, we must solve tough problems around material consistency, process control, and certification. With this funding, we’re taking a huge step forward”.

Marcus Pont, CEO

Why it matters

L-PBF is flight-proven, but wider uptake is constrained by end-to-end productivity gaps, fragmented data/QA, and reliance on overseas steps (powder, HIP, advanced heat-treat). DECSAM closes those gaps by linking UK materials supply, machine capability, in-process quality assurance, a robust digital thread, and factory scale-up—so parts are repeatable, cost-competitive, and producible at volume in the UK, supporting net-zero 2050.

The programme is business-case led: recycled/UK-made powders; optimised build and nesting; in-process monitoring with closed-loop control to reduce or eliminate HIP/CT where feasible; and parameter/alloy development to cut finishing time. Cost-modelled demonstrators (e.g., an aircraft floor beam) show the shift from today’s “as-is” to a digitally connected, production-ready “to-be” at a cost point which enables AM to buy its way into serial aerospace production.

Focus use cases include ultra-efficient wing & engine structures and hydrogen subsystems (conformal heat exchangers, fuel-cell manifolds). Alongside performance gains, DECSAM mitigates single-source casting risks, on-shores critical pre-form manufacture, and advances compact AM-enabled actuation toward power-by-wire—delivering more right-first-time, certifiable parts, shorter lead times, a resilient UK supply chain, and cleaner aerospace manufacturing.

DECSAM at a glance:

- Value & timing: £38 million ; June 2024 – June 2028 (48 months).

- Leadership: Airbus (project lead) with 11 project partners across OEMs, Tier-1s, SMEs, RTOs and academia.

- Innovation pillars: Performance, Productivity, Scalability, Demonstration for L-PBF.

- Planned outputs: Ground and flight demonstrators; recycled/reused powder routes; in-process monitoring with closed-loop control; a connected digital thread; factory design for scale-up; and clear pathways to qualification and certification.

Funding acknowledgement: This work is supported by the ATI Programme: a partnership of the Aerospace Technology Institute, the Department for Business & Trade and Innovate UK.

Notes to editors: Consortium: Airbus Operations Limited (lead), Renishaw plc, ASTM International UK, Authentise Ltd, The Manufacturing Technology Centre Limited, GKN Aerospace Services Limited, Additive Manufacturing Solutions Ltd, APEX Additive Technologies Ltd, Domin Limited, University of Sheffield, and ToffeeX Limited.

Media contacts: enquiries to uk@astm.org