FRANKFURT, Germany — November 18, 2025 — ASTM International’s Advanced Manufacturing Division (AMD) is exhibiting at Formnext 2025, announcing a series of milestones that illustrate its expanding global role in shaping the future of additive manufacturing (AM).

Key highlights include new U.S. defense and aerospace collaborations through America Makes, participation in the UK-funded £38 million DECSAM program, the first certifications under ASTM’s Additive Manufacturing Certification Program, a new semiconductor supply chain qualification partnership, publication of a global Directed Energy Deposition (DED) whitepaper capturing industry perspectives, and the unveiling of the new ASTM Market Intelligence Platform a continuously updated ecosystem for AM market intelligence.

Together, these initiatives showcase ASTM’s unified vision for advancing technology from readiness to adoption through technical development, insight, and certification. More details will be discussed during a press conference at the ASTM International/Wohlers Associates booth at Formnext on Tuesday, November 18, from 4:00–4:30 p.m. (Hall 11.0, Stand A21).

ASTM INTERNATIONAL DEEPENS AMERICA MAKES PARTNERSHIP TO STRENGTHEN U.S. MANUFACTURING RESILIENCE

In the United States, ASTM International has deepened its collaboration with America Makes, the nation’s leading public-private partnership for additive manufacturing, through a series of new initiatives that advance industrial readiness and defense innovation.

Under the Quality Test and Inspection Methods Expediency (QTIME) project—funded by the Office of the Under Secretary of Defense, Manufacturing Technology (OSD ManTech)—ASTM’s Additive Manufacturing Center of Excellence (AM CoE) is leading the Industry Transition Team (ITT) to connect research outcomes with qualification and production use across aerospace, defense, and energy sectors. The ITT brings together Boeing, Lockheed Martin, SAE International, Baker Hughes, and Wohlers Associates, focusing on developing faster, more cost-effective non-destructive inspection (NDI) techniques for large and complex AM parts.

Building on that effort, ASTM and NASA, through America Makes, have launched WATCHLIST (Workshop on Additive Techniques for Control and Health-Monitoring Leveraging In-Situ Technologies) — a collaborative roadmap for in-process monitoring and control designed to improve process reliability, accelerate qualification, and strengthen U.S. supply-chain security.

ASTM has also been elevated to Platinum Membership within America Makes, joining a select group of organizations shaping national additive manufacturing strategy and advancing standards-based qualification pathways for industrial-scale adoption.

“From QTIME’s transition engine to the WATCHLIST roadmap and our Platinum membership, these steps knit together the full lifecycle—from sensing and control to qualification and adoption,” said Dr. Mohsen Seifi, ASTM International’s Vice President of Global Advanced Manufacturing Programs. “Our goal is simple: make additively manufactured products trusted, certifiable, and deployable at scale.”

Full press release available here.

ASTM International UK Joins £38M DECSAM Program to Scale Sustainable Aerospace Additive Manufacturing

ASTM International UK, a newly established branch of the organization, has joined the Digitally Enabled Competitive & Sustainable Additive Manufacturing (DECSAM) project, a £38 million, four-year UK aerospace program led by Airbus and funded through Innovate UK, the Aerospace Technology Institute (ATI), and the UK Department for Business & Trade.

The project will develop and deploy the latest AM technologies — such as beam shaping and in-situ process monitoring — to make metal laser powder bed fusion (L-PBF) more cost-effective, productive, and sustainable for flight-ready parts.

By prioritizing resource efficiency, material reuse, and circular design principles, DECSAM aims to reduce waste and carbon intensity across the AM value chain, supporting the aerospace sector’s transition toward net-zero manufacturing.

ASTM will play a leading role in amplifying DECSAM’s outcomes, ensuring that its findings, standards insights, and adoption pathways reach the global manufacturing community through its UK-based AM operations and world-class Additive Manufacturing Center of Excellence (AM CoE).

“The UK government’s investment in green aerospace innovation is a strong signal that sustainable manufacturing is both a national priority and a global opportunity,” said Andrew G. Kireta Jr., President of ASTM International. “DECSAM exemplifies the kind of industry-led collaboration needed to unlock additive manufacturing’s potential at scale — and ASTM is proud to contribute to its success.”

(Full DECSAM release, including roles and quotes from partner companies available here.)

KSB and AM Craft Become First Companies Certified Under ASTM’s Additive Manufacturing Certification Program

ASTM announced that KSB, a global leader in pumps, valves, and fluid systems headquartered in Pegnitz, Germany, and AM Craft, a polymer AM specialist for aircraft interiors based in Riga, Latvia, have become the first two organizations to achieve ASTM Additive Manufacturing Certification under the AM CoE’s newly launched audit framework.

Developed by the Additive Manufacturing Certification Committee (AMCC) — a cross-sector body representing more than 25 leading organizations including Boeing, Lockheed Martin, Safran, Ford, and Stryker — the program integrates ISO/ASTM 52901, 52904, and 52920 into a single unified framework for AM quality assurance.

Unlike general-purpose quality management systems such as AS9100 or ISO 9001, the certification provides an AM-specific audit addressing process control, traceability, and risk management across all seven AM process categories.

“This certification creates the first globally recognized, cross-industry benchmark for additive manufacturing quality,” said Dr. Khalid Rafi, Director of Training and Certification Programs for ASTM International. “It helps manufacturers demonstrate readiness, gain customer trust, and accelerate adoption in critical applications.”

ASTM plans to expand its Qualified Manufacturer List (QML) in early 2026, promoting transparency and standardization across the AM supply chain.

MIRDC-AMCen Philippines Achieves Dual AM Certification Milestone

ASTM International and the Metals Industry Research and Development Center–Advanced Manufacturing Center (MIRDC-AMCen) under the Philippines’ Department of Science and Technology (DOST) held a ceremony in Manila, marking MIRDC-AMCen’s achievement as the first organization in Southeast Asia to receive both AMQ (Qualified Facility) and AMFS (Facility Safety) certifications from ASTM.

The MIRDC-AMCen is the Philippines’ national hub for AM and smart technologies. Operated under the Department of Science and Technology, MIRDC-AMCen leads public-sector efforts to advance industrial innovation, workforce development, and regional competitiveness through emerging technologies.

This milestone reflects MIRDC-AMCen’s growing role as a regional model for AM excellence, combining national R&D with global best practices in safety and quality. The certification recognizes MIRDC-AMCen’s leadership in establishing a robust and secure AM facility aligned with international standards, advancing Southeast Asia’s readiness for industrial adoption.

As a partner for ASTM, MIRDC-AMCen gives the international organization a broader footprint in Southeast Asia, where the rise of friendshoring has seen new advanced manufacturing operations take root. This relationship will allow ASTM to better serve the region as it increases its presence in the region.

ASTM and Additive Center Partner to Elevate AM Supply Chain Quality for the Semiconductor Industry

ASTM International’s AM CoE has announced a new partnership with Additive Center B.V. (Eindhoven, Netherlands) to establish the first semiconductor-specific AM supplier qualification pathway under the aforementioned AM Certification Program.

The collaboration connects Additive Center’s expertise in semiconductor manufacturing ecosystems with ASTM’s globally recognized certification and qualification frameworks, providing a model for AM quality assurance in one of the world’s most advanced high-tech industries.

Driven by a leading chip manufacturer’s initiative to enhance its AM supply chain, the partnership will help suppliers progress from readiness to recognized certification, applying the same rigor that has defined quality assurance in aerospace, defense, and medical manufacturing.

“ASTM brings certification and standardization experience from the most regulated industries into the semiconductor space,” said Sergio Sanchez, Business Director of ASTM’s Advanced Manufacturing Division. “Together with Additive Center, we’re helping suppliers achieve the precision and repeatability this industry demands.”

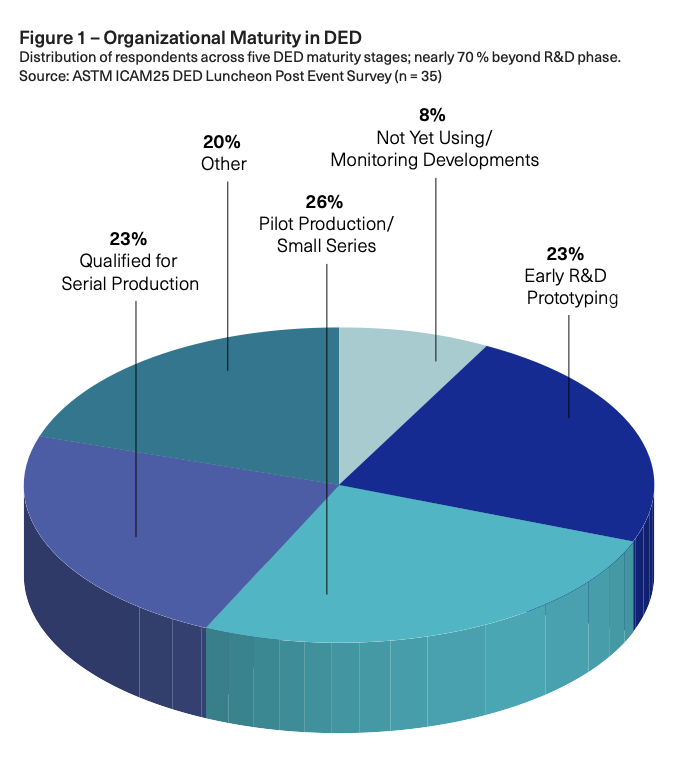

New White Paper Charts Global Pathway for Directed Energy Deposition (DED) Standardization

ASTM has published a new white paper, “Accelerating Industrial Readiness in Directed Energy Deposition (DED),”co-authored by Josh Barras, Additive Manufacturing Principal Engineer for Global Business Development & Innovation Strategy at ASTM International, and Dr. Carl Hauser, Technical Fellow for Metal AM at Wohlers Associates.

The paper synthesizes insights from more than 50 global experts who participated in ASTM’s International Conference on Advanced Manufacturing (ICAM) 2025 DED Luncheon in Las Vegas. It identifies three industry priorities essential to large-scale adoption of DED:

- Unified qualification and certification frameworks across sectors,

- High-quality, traceable materials data, and

- Process calibration and consistency to ensure reproducibility.

The findings will inform ASTM’s roadmap for DED standardization and guide formation of a DED Community of Practice under the Consortium for Materials Data and Standardization (CMDS).

Barras is an awardee of the UKRI Future Leaders Fellowship, a seven-year personal grant that he has chosen to complete with ASTM. Barras will present the work’s highlights at Formnext 2025, continuing ASTM’s leadership in advancing confidence and comparability in metal AM processes.

Wohlers Report Evolves into a Live Market Intelligence Platform

For more than 25 years, the Wohlers Report has been the AMg industry’s most trusted source of data and analysis. ASTM is now launching the next evolution: the ASTM Market Intelligence Platform, a continuously updated digital environment delivering real-time insights, analytics, and advisory integration.

The new platform transforms the Wohlers Report from a static annual publication into an interactive, living intelligence ecosystem. Users will have access to dashboards, datasets, and analytical tools powered by a continuously refreshed database spanning the AM value chain.

“The new Wohlers Platform is faster, smarter, and designed to empower decision-makers,” said Dr. Mahdi Jamshid, Head of Market Intelligence at ASTM International. “It helps organizations interpret data, validate strategies, and make confident investment and production decisions in real time.”

Select customers are participating in the beta program, with a full public release planned for early 2026.

A Unified Vision for Advanced Manufacturing

These initiatives — spanning U.S. defense, sustainable aerospace, semiconductor supply chains, certification, metal AM readiness, and digital market intelligence — reflect ASTM’s broader mission to advance global manufacturing through trust, transparency, and technology.

By integrating the AM CoE and Wohlers Associates with additional work into new technologies, ASTM’s Advanced Manufacturing Division is uniting technical research and development, certification, training, standards, and insight under one framework: helping the world move from readiness to adoption of advanced manufacturing.

“ASTM’s role is not just to define standards — it’s to connect them to industry reality and future readiness,” said Dr. Mohsen Seifi, Vice President of Global Advanced Manufacturing Programs at ASTM International. “From sustainable aerospace manufacturing to global certification frameworks and live data intelligence, ASTM is shaping the infrastructure of advanced manufacturing for decades to come.”

ASTM at Formnext 2025: Speaker Lineup and Press Conference

ASTM will host a press conference on Tuesday, November 18, from 4:00–4:30 p.m. (Hall 11.0, Stand A21) to discuss these announcements and ongoing global initiatives.

Visit ASTM International/Wohlers Associates at Hall 11.0, Booth A21 to meet experts from the AM CoE and Wohlers Associates and to learn how ASTM is helping industries around the world move from readiness to adoption of advanced manufacturing technologies.

Media Contact:

Michael Molitch-Hou

+1.323.868.1865

mmolitch-hou@astm.org