About the Course

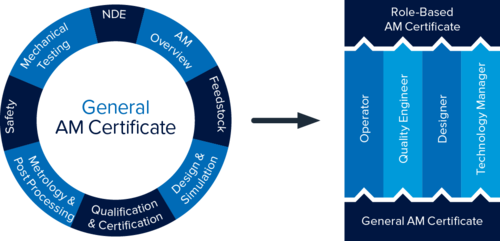

The AM General Personnel Certificate Course is comprised of 8 modules that cover all the general concepts of the AM process chain. To give flexibility to the attendees, the course is scheduled such that two modules will be covered every week to complete the entire course in one month

This course will equip attendees with core technical knowledge related to common AM practices and will allow them to earn a General AM Certificate that will serve as the foundation and pre-requisite for earning future specialized role-based AM certificates through the ASTM AM CoE. Attendees will complete a multiple-choice exam upon course completion.

Who Should Attend?

Whether you are just stepping into AM or if you have experience and are looking to advance your knowledge and stay relevant, the General Personnel Certificate Course is for you. The course is recommended for technicians, managers, engineers, and other individuals from government agencies, industry, and academia with any level of AM experience.

Why Sign Up for This Course?

- Gain core foundational technical knowledge covering the entire AM process chain

- Stand out in the industry with ASTM E2659-18-compliant certificate from the globally recognized ASTM AM CoE

- Chart your own path: This course is the first step toward multiple AM CoE role-based certificates

- Each module taught by experts from academia, industry, national labs, and regulatory bodies

EARN A DIGITAL BADGE after successful completion of this course. These badges are an innovative way to showcase career knowledge, skills, and abilities obtained through professional development. Add the badges to your digital portfolios or share them on social and professional networks.

Course attendees interested in receiving 3.2 Continuing Education Units (CEUs) should complete a CEU application form. A certificate will be sent electronically to the attendee approximately 1-2 weeks following successful completion of the exam.

Course Schedule

This course will feature 18 experts across the field of additive manufacturing to provide a comprehensive course covering all of the general concepts of the AM process chain to its attendees. Attendees will be given virtual access to two modules per week for self learning and then a live Q&A session with course instructors will be held the following week to review content.

Instructors

-

Rachael Andrulonis

-

David L. Bourell

-

Olaf Diegel

-

Matthew Di Prima

-

Michael Gorelik

-

Richard Leach

-

Louis-Philippe Lefebvre

-

Royal Lovingfoss

-

Frank Medina

-

Francois Richard

-

David W. Rosen

-

Don Roth

-

Nima Shamsaei

-

Tony Thornton

Organizers

For more information, please contact:

Dr. Nima Shamsaei

Auburn University

shamsaei@auburn.edu

Ms. Rachael Andrulonis

WSU – NIAR

rachael@niar.wichita.edu

Dr. Khalid Rafi

ASTM International

krafi@astm.org

Dr. Mohsen Seifi

ASTM International

mseifi@astm.org

Online Learning

Attendees will be provided access to ASTM International’s Learning Center to complete this training. This access will include training videos and course work for each module of this Certificate Course.